Antifreeze and Coolants

- With winter approaching in Europe, Antifreeze and Coolants generally get some more -well deserved- attention than usual. In this article we highlight in short why it is important to pay attention to this fluid and what the main differences are between the fluids in the North Sea Lubricants portfolio.

Function of the cooling system

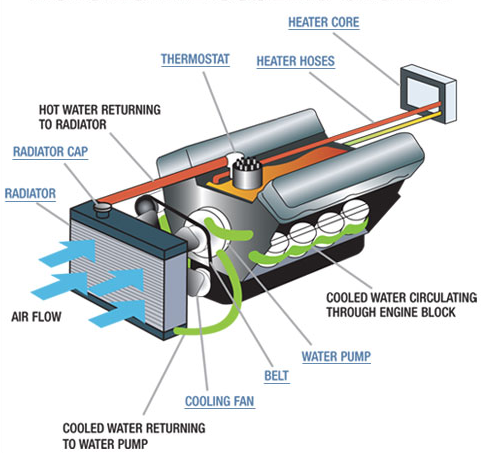

The ‘engine cooling system’ is a complex system; consisting

of many different materials such as rubber hoses, aluminum or copper radiator and cast-iron or aluminum engine blocks. These materials have high temperature differences and different flow-rates within the system.

of many different materials such as rubber hoses, aluminum or copper radiator and cast-iron or aluminum engine blocks. These materials have high temperature differences and different flow-rates within the system.

The primary function of the cooling system is to dissipate excess heat that is produced by the engine during operation. The heat is absorbed by the coolant and transferred to the radiator. The radiator works as a heat-exchanger and the heat is transferred to the outside air.

Coolant

The best possible liquid to absorb heat and to keep the engine cool is water. However, water has some major disadvantages:

- Water freezes at 0⁰C

- Water boils at 100⁰C

- Water is corrosive to most metals in the system

For this above three reasons, additives are used to enhance the properties of plain water into a suitable coolant. The added components are:

- Corrosion inhibitor: added protection against corrosion and therefore reducing the formation of blockages in the system and/or damages to waterpumps.

- Anti-foam additive: prevents air bubbles from forming. Air is a good insulator, any air that is not released can decrease the coolants ability to absorb and release heat.

- Lubricant: added for protection of waterpumps and seals. When not lubricated wear is increased and noise and leaks are more likely to occur.

The difference between antifreeze and coolant:

Antifreeze is an undiluted product to produce coolant. It consists 95-95% of Mono Ethylene Glycol (MEG) and 5-10% additives.

Coolant is a mixture of antifreeze with demineralized water in 50/50% ratio.

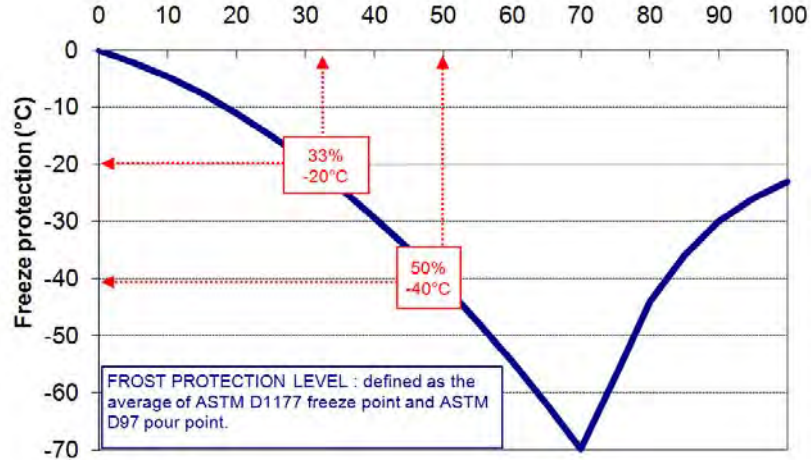

The frost protection varies with the percentage of antifreeze in water. A common modern antifreeze/water mixture is as follows:

The optimum mixture ratio is a compromise between frost protection and heat transfer capabilities.

According to the chart above, the best possible frost protection will be achieved with a mixture of 70% antifreeze and just 30% water. But because of the little amount of water, this mixture has severely less heat transfer capabilities and that could cause overheating of the engine. Therefore, most of the standard ‘ready-to-use’ coolants consist of 50% antifreeze and 50% water. In most cases this provides sufficient frost protection for the majority countries, while still providing excellent heat transfer properties.

Types of antifreeze

The majority of the market can be divided in main types of antifreeze:

- Traditional antifreeze

MEG based with mineral inhibitors. Traditional antifreeze is primarily used for older applications. In the NSL portfolio: GLACIER ANTIFREEZE and GLACIER COOLANT RTU 40 are traditional antifreezes and coolants.

- OAT antifreeze

MEG based with organic corrosion inhibitors (Organic Acid Technology). It is a silicate-free product. These antifreezes are capable of much longer drain intervals than the traditional antifreezes. It is usually ‘filled for life’ or at least 150.000 km. GLACIER ANTIFREEZE G12+ and GLACIER COOLANT RTU G12+ are the OAT antifreeze and coolant in the NSL range.

- Hybrid Antifreeze

MEG based with both mineral and organic inhibitors. Also called ‘HOAT-type’ which means: ‘Hybrid Organic Acid Technology.’ This type of antifreezes contains silicate. They are capable of longer drain intervals than traditional antifreeze, but less than OAT-type. Suitable for a very wide variety of vehicles of previous generations. North Sea Lubricants has GLACIER ANTIFREEZE XL and GLACIER COOLANT XL in its range.

- Lobrid Antifreeze

MEG based with organic corrosion inhibitors and small amounts of mineral inhibitors. Low silicate content. MEG sometimes can be partially replaced with glycerol for less environmental impact. Lobrid antifreeze has a very high temperature protection for aluminum engine blocks and the longest possible drain intervals. North Sea Lubricants offers GLACIER ANTIFREEZE G12++ and GLACIER ANTIFREEZE G13.

Do you need more advice about the exact applications of antifreeze and coolants? Please consult the North Sea Lubricants Oil Advisor on the website or contact our Customer Service Center at csc@northsealubricants.com